Cement is the component in concrete that causes the mixture to harden into a stone-like material when water is added. Portland cement is the traditional type used. Due to the robustness of the cured concrete, simplicity of use, and versatile applications, concrete is a very widely used building material.

However, the production and processing of concrete cause as much as 6% of the global CO2 emissions (Abergel, 2019). In order to comply with the Raw Materials Agreement (IenW, 2017), an important strategy is to use new recipes to use concrete with lower CO2 emissions combined with 3D printing for material reduction.

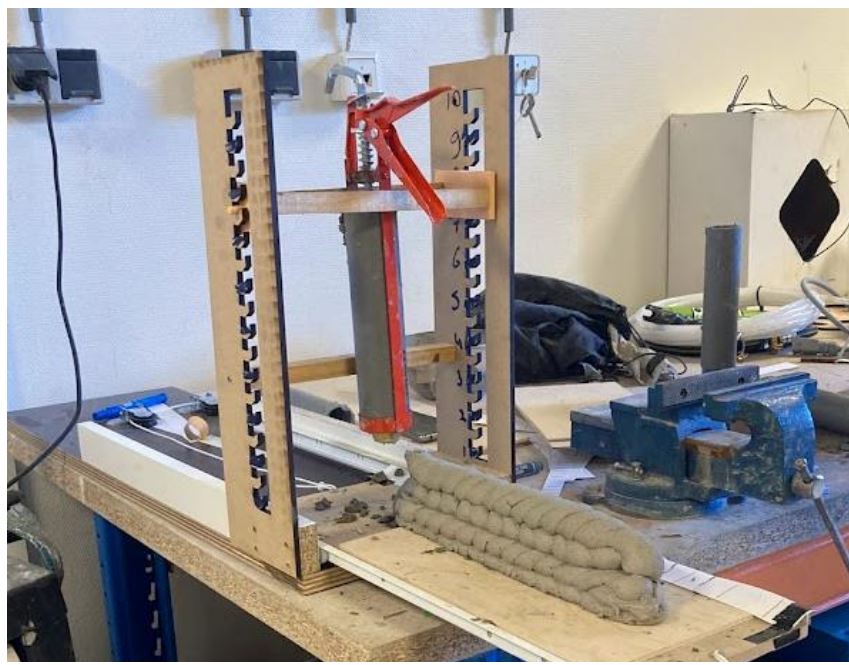

The advantage of 3D printing is that material is applied is provided where necessary. This makes the processing material-efficient compared to concrete poured into the formwork. At the same time, 3D concrete printing requires a delicate composition of the recipe: It must be fluid enough to allow movement from the mixer to the print head, but at the same time cure sufficiently fast to be able to bond to the next layer.

Within the previous projects, the mixes used were based on conventional cement (Portland and blast furnace cement). However, a more sustainable trajectory of development would be to switch to lower CO2 emissions recipes.

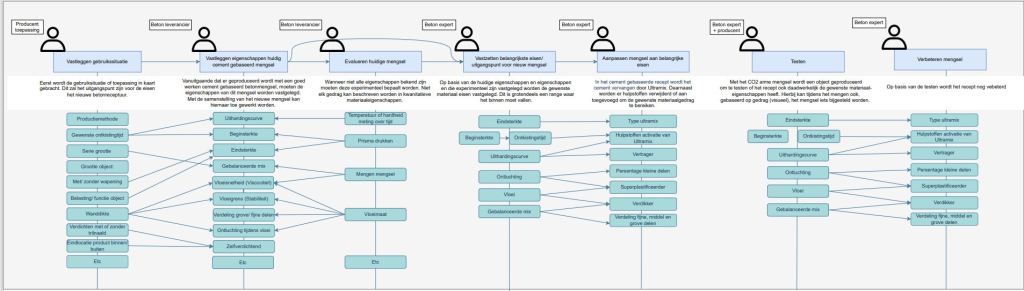

After the innovation demand by Rouwmaat, Ecocem‘s Low-CO2 cement recipe was made available so that research can be done together with the ID research group to answer the question:

How variations in the mix of low-carbon concrete can be combined with 3D printing and casting to obtain desired product properties?

Creastone produces outdoor ornaments, such as a water fountain sphere. As a case study, copies of one or a few products will be made by means of 3D printing. The advantage of this approach is that product properties such as strength, water permeability, bearing capacity, density, and environmental costs can be compared with the performance of the existing product produced by casting in a mold.

From mixing to printing

From testing to casting