Together with our team, partners from the industry and students of diverse backgrounds, we developed a 3D concrete printer within the framework of the RAAK-MKB project KONKREET. We investigated not only the technical possibilities of the new technology but also applications that could truly take advantage of the new production method and answer real-life needs of the product design and construction sector.

The full list of topics investigated during the project includes:

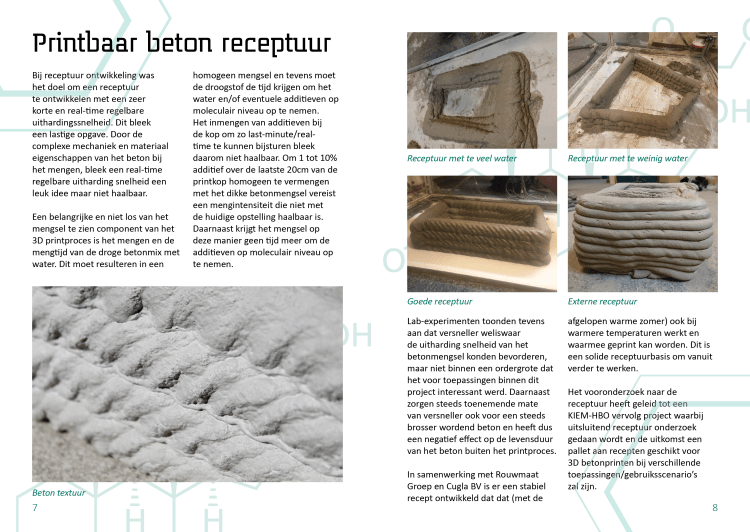

- various recipes for 3D printable concrete

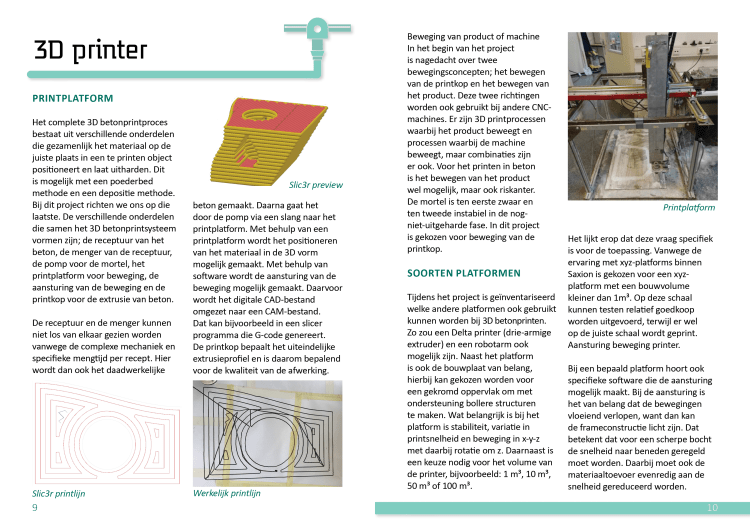

- configuration and control of the printer developed by the team

- printing strategy and slicing of complex geometries

- up-scaling

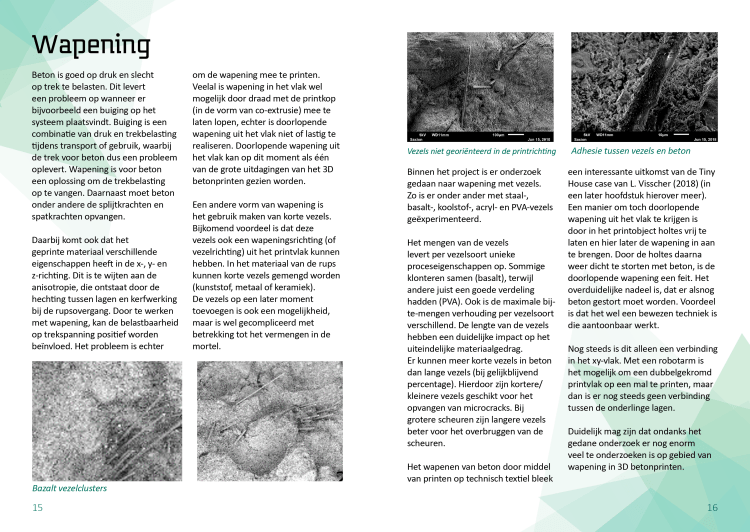

- reinforcement

- mix at the print-head with fast hardeners

- undercuts and support

- parametric modeling and generative design

Applications developed during the project:

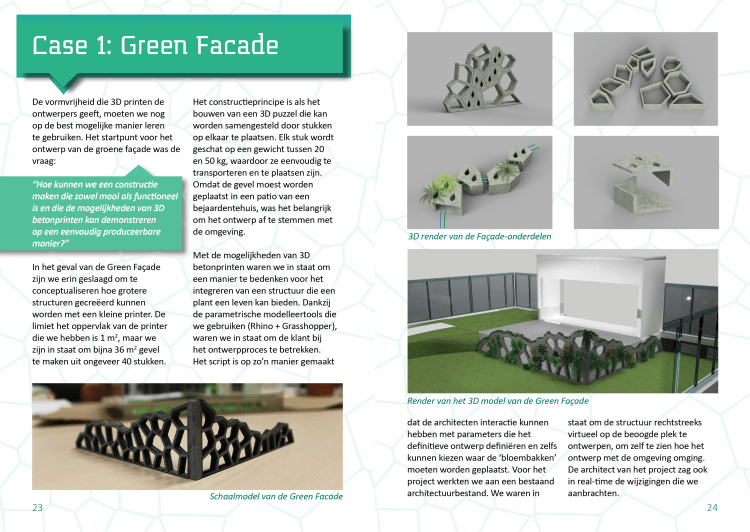

- Green Facade – a fence for an inner garden of a care complex.

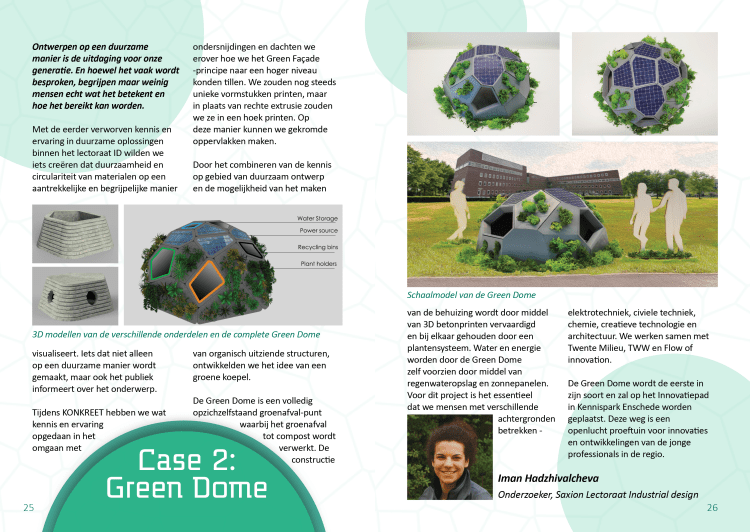

- Green Dome – a composting unit intended for the Flow of Innovation and Enschede.

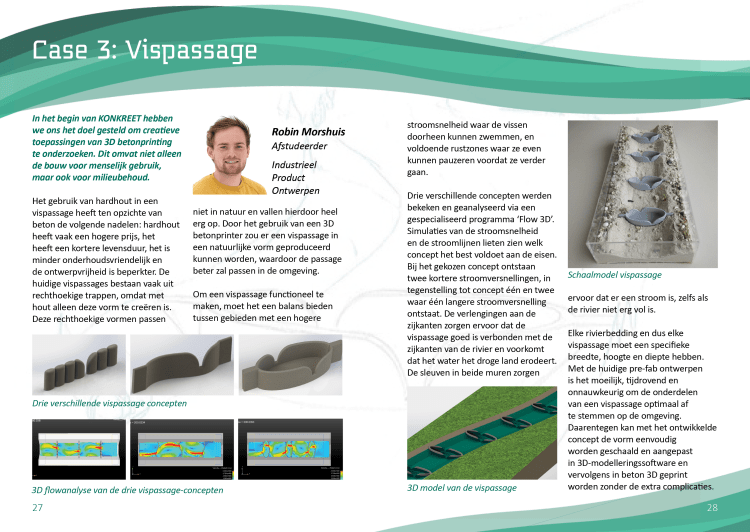

- Fish ladder – passage for migrating fish

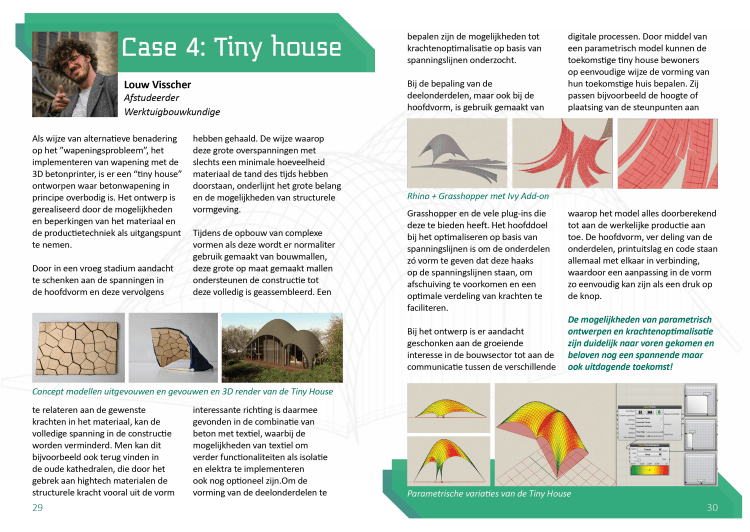

- Tiny House – concrete shell printed on top of a textile sheet

The 3D printer in Saxion was made suitable for research purposes and small batches. To bring the Green Facade to life, we needed strong industrial partners. We got in touch with Vertico who delivered high quality 3D concrete printing and Trebbe, who ensured safe and professional build-up.

The Green Façade is the first 3D concrete printed structure in Twente realized by the cooperation between Saxion Industrial Design Research Group, De Witte van der Heijden Architecten, Vertico Large Scale 3D printing and Trebbe.

George de Witte from De Witte van der Heijden suggested that the structure be created for the interior garden of Stepping Stones’ building realized by Trebbe. The basic design was developed by Iman Hadzhivalcheva with project manager – Ivo Vrooijink.

The final design was made via parametric modelling in which each piece was made to have unique form, fit on a palette for easier transportation and weight under 50 kg so the big structure can be built by stacking the pieces on top of each other by two people.

The 50 unique elements were printed using our large ABB robot arm and a gantry by Rohaco. The façade weights approximately 2,5 tons. The transport and installation was managed by Trebbe.

One thought on “KONKREET”