Introduction

The big boys in 3D concrete printing (Bruil, Cybe, Witteveen + Bos, BAM and more) profile themselves with a lot of publicity with “the first printed house”, “the first serial project” and “the first 3D printed bridge”. However, if you take a closer look at this, entire parts of the house are delivered in traditional prefabrication (floors) and reinforcement is done in the traditional way (bridge). Are these the innovative breakthrough applications that this challenging technology promises us? With regard to the technology of 3D concrete printing, steps have been made in the last 4-5 years, but the development of the application is lagging behind.

In recent years, the Saxion research group ID also has explored 3D concrete printing together with a number of partners. 3D concrete printing was so new that in the RAAKmkb project KONKREET – due to the lack of usable existing equipment – we realized a working printer, a good recipe, and a number of applications from scratch.

Now that the printing technique has been somewhat mastered and the first companies with commercial 3D concrete printers have entered the market, a shift is needed from focus on technology development to the development of 3D concrete printing applications. Technologically there is still a lot to be researched, but the applications should be leading in this. Without challenging and cost-interesting applications, the development of 3D concrete printing has no future. But how do we find that application? In recent years there has also been a real search for relevant applications and the discovery of a new way of thinking and designing.

The big challenge for SMEs lies in finding interesting applications. When is it interesting for me as a company?

In this project, a broad consortium with parties from the entire construction chain – contractors, architects, raw material suppliers – but also network partners, design offices, and potential users aims to find a solution for the demand for interesting applications of 3D concrete printing. To this end, we are investigating a selection method and redesign method for application-oriented design in 3D printing technology, with corresponding business case (s).

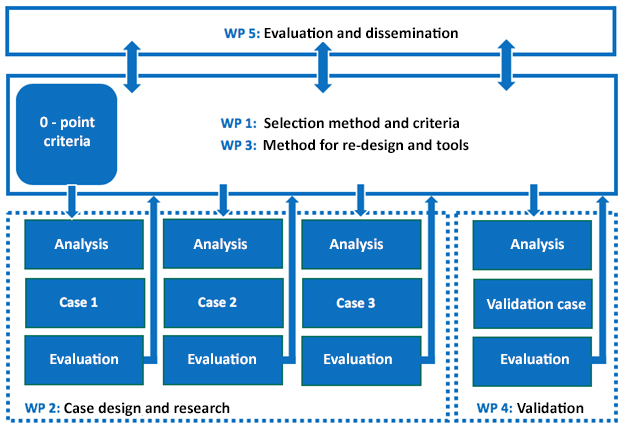

Planning (WP = Work Package)

Research methodology

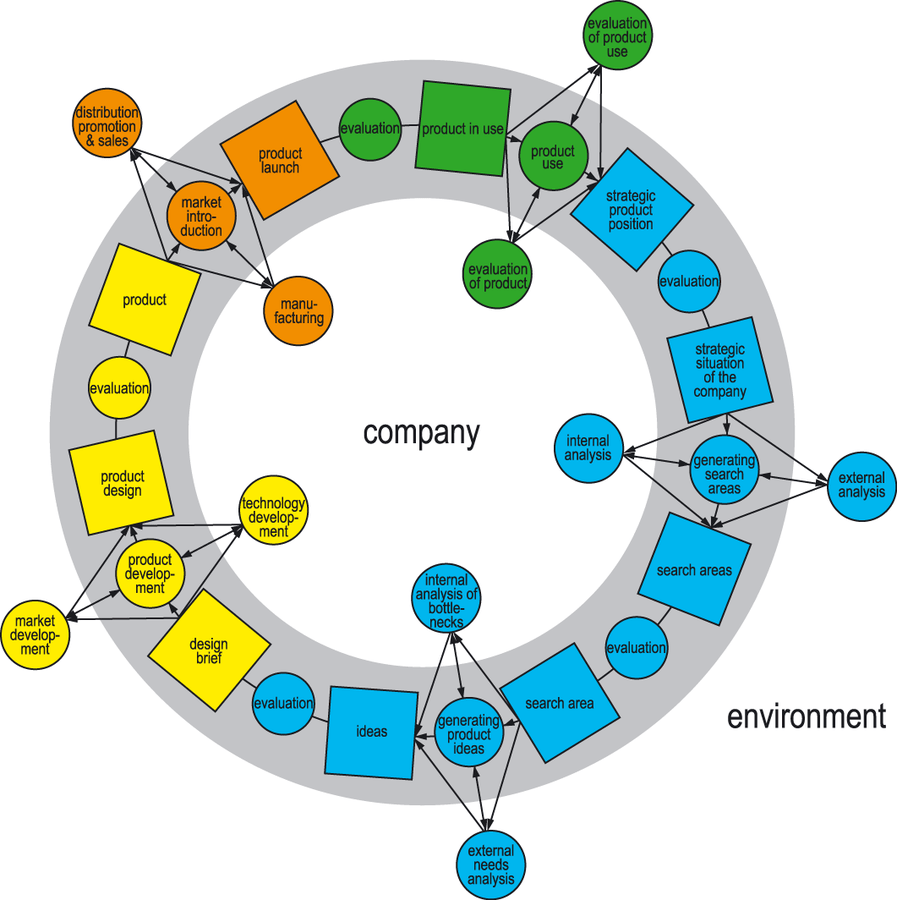

When answering the research question, but especially for the development of both the selection method and the (re) design tooling, a systematic approach is used based on the Delft Innovation Model (DIM). Good experience has previously been gained with this approach in the development of the 3D metal print selection tool and the Innovative Materials Platform Twente, where promising new applications with innovative materials were sought.

Analogous to the DIM model, the possibilities (the “strengths”) of a material are linked to possible applications/markets (the “opportunities”) to generate (product) ideas. In the next phase, the technological possibilities are linked to the needs of the user/market in a product concept. It is an iterative process in which with each iteration an improvement is made in the selection method and the (re) design tooling.

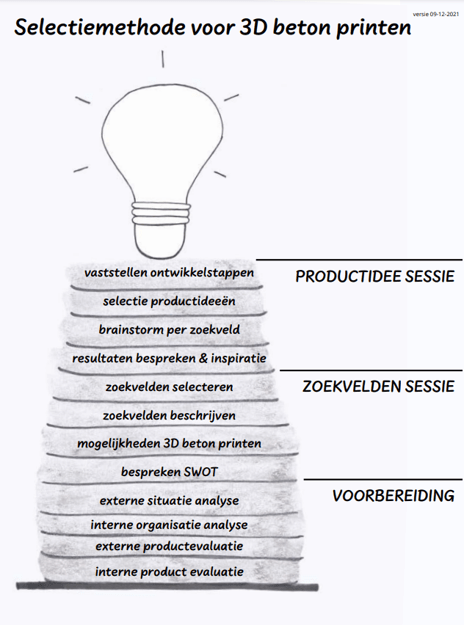

Selection method

3D concrete printing is exciting but when does it become profitable to use and for what?

Within Konkreter we are developing, together with our partners, a selection method that could help companies identify new potential applications, business cases, and markets for the technology.

Within three assisted sessions, businesses can internally analyze areas of interest and potential new products or re-design of the existing portfolios.

The sessions are conducted with the help of cards combining current trends with perks of the technology. This way the participants are invited to think outside the context of their own and the company background.

Cases

Staircase

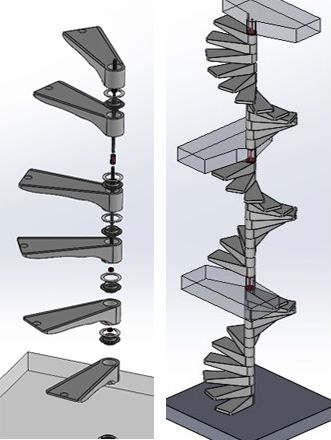

For printing a concrete staircase, reinforcement is almost always required. Within this case, it was investigated which reinforcement techniques can be applied within the printing process that is also suitable for implementation in a staircase. In addition to arming a staircase, we looked at which shapes could be interesting for 3D print.

By printing the stairs, other shapes are possible than when casting a staircase. One of the concepts found to be interesting for the project partners is a spiral staircase. The first prototypes showcased how with 3D concrete printing each step can be a slightly different shape without complicating the production process. The first results contained 4x less concrete in comparison to traditionally casted ones.

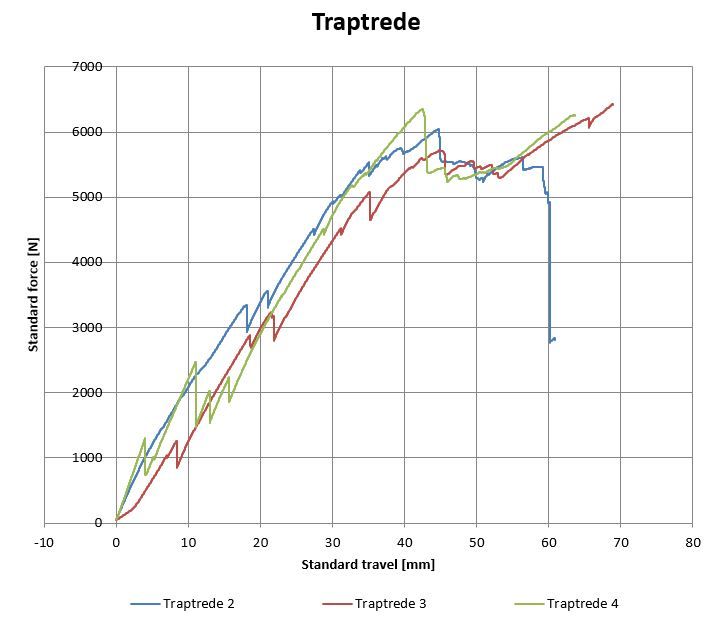

Further developments resulted in a parametric model of a spiral staircase, 3D printed it in the Saxion 3D concrete print lab and our team conducted a pressure test at the Mechanical lab of the Production technology group Universiteit Twente to evaluate the stairsteps.

According to NEN-EN-1991-1-1, a staircase for an office location must withstand a point pressure point of 4,5kN (including the safety factor). The results show a consistent performance at started to collapse at 6kN. This brings more confidence in the design and manufacturing method and therefore 3D concrete printed stairs are one step closer to real-life application. With parametric design a staircase can be made to fit almost any setting, the client wishes all while being responsive to last-minute changes.

We believe 3D concrete printing shouldn’t stay in the lab and we’re very excited to work towards implementing our designs in the real building setting! Several concepts were developed for office and living settings.

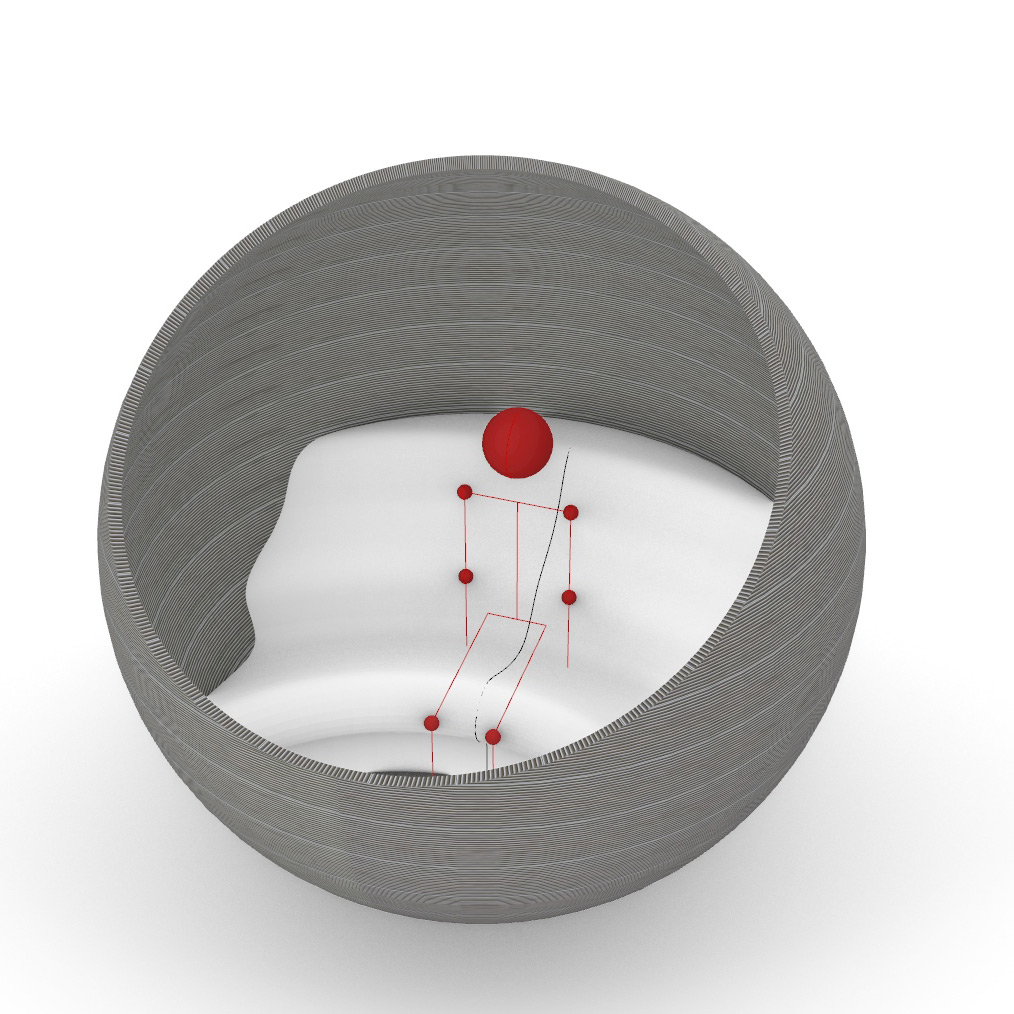

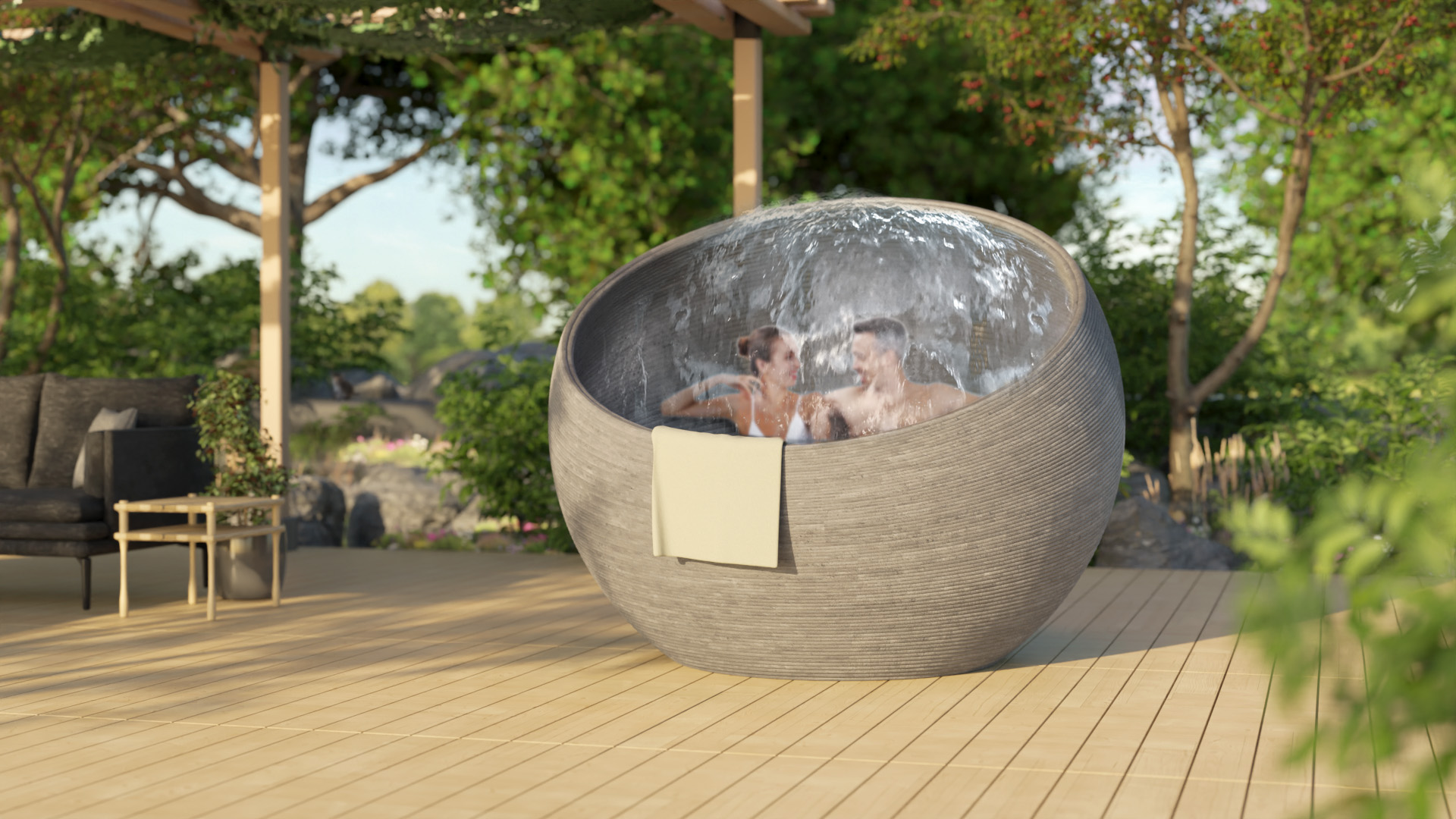

Hot tub

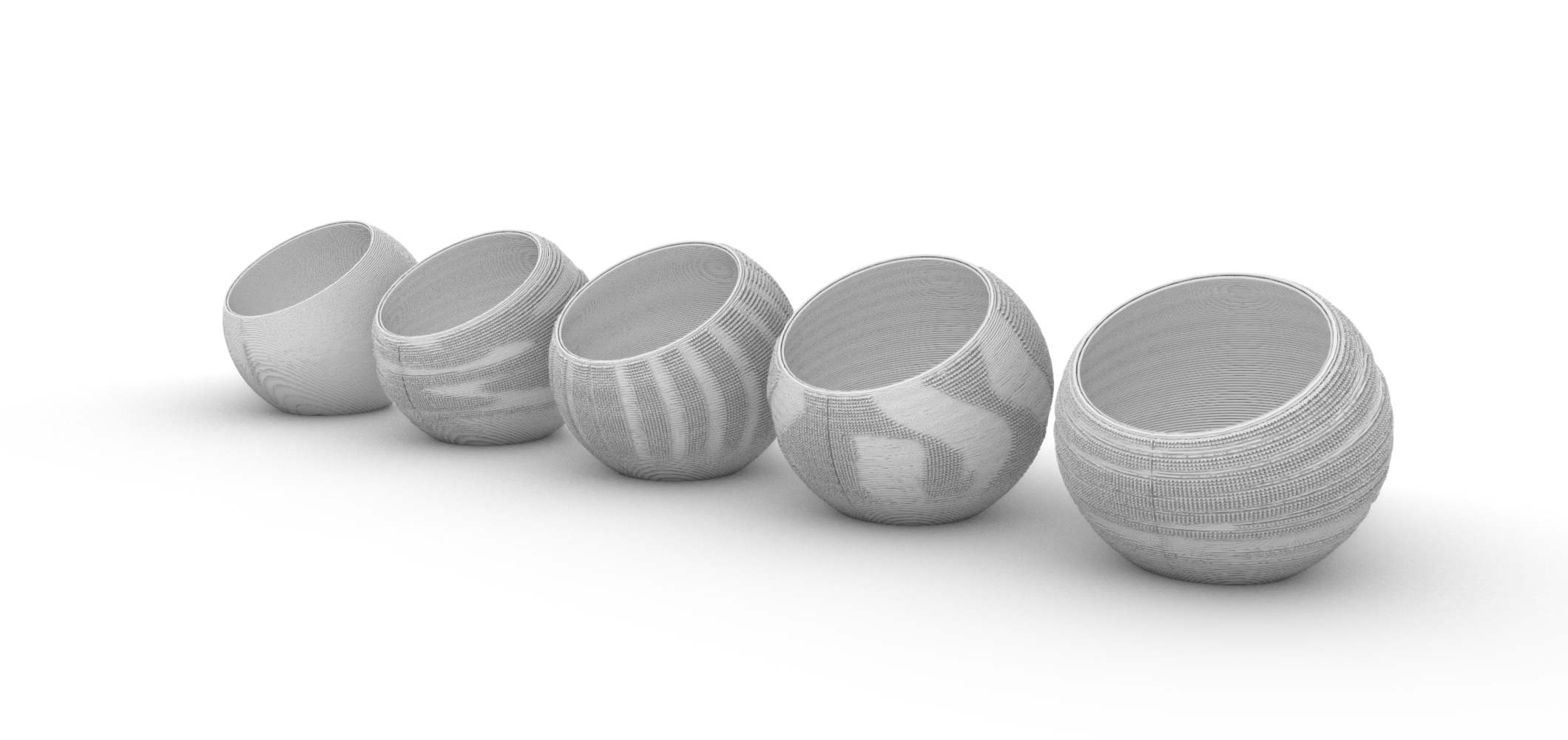

Creastone specializes in hand-made water ornaments for the garden. The signature sphere is offered in fixed sizes and can be combined with a fountain, fire, lighting, and greenery.

3D concrete printing in combination with parametric modeling offers great flexibility in terms of product dimensions and textures. The first 3D printing experiments were done in our Saxion 3D Concrete Printing lab. Two sphere sizes (60 cm & 90 cm diameter) were printed successfully and various techniques were explored to get the beveled edge on the inside of the sphere.

60 cm diameter at 6 mm layer height:

Edge printing over a 3D printed mold & over a robotically sand-formed mold. Exploration of hybrid printing over partial molds:

The available space within the Saxion’s concrete lab allowed for a scale-up of the design up to a 90 cm sphere. The object was printed up-side-down and clay balls were used to support the inside of the structure. The sphere was printed successfully over a sandbed mold for the beveled edge.

90 cm diameter at 8mm layer height:

Water feature + jacuzzi?? Why not?

The signature sphere from Crastone could also be offered as a hot tub or a jacuzzi if scaled up. And this was the new challenge ahead.

With the know-how from the smaller scale prints, we prepared a 150cm diameter sphere with an irregular slicing strategy. This time the sphere would be printed from the bottom up and the layers would be thinner at the front and thicker at the back by regulating the print speed. The larger print required a larger printing set-up as well. Our partners at Vertico were able to help here with a larger reach of a robot and a 2-component nozzle. Make sure to check the video below!

175 cm diameter (print at Vertico):

And it works!

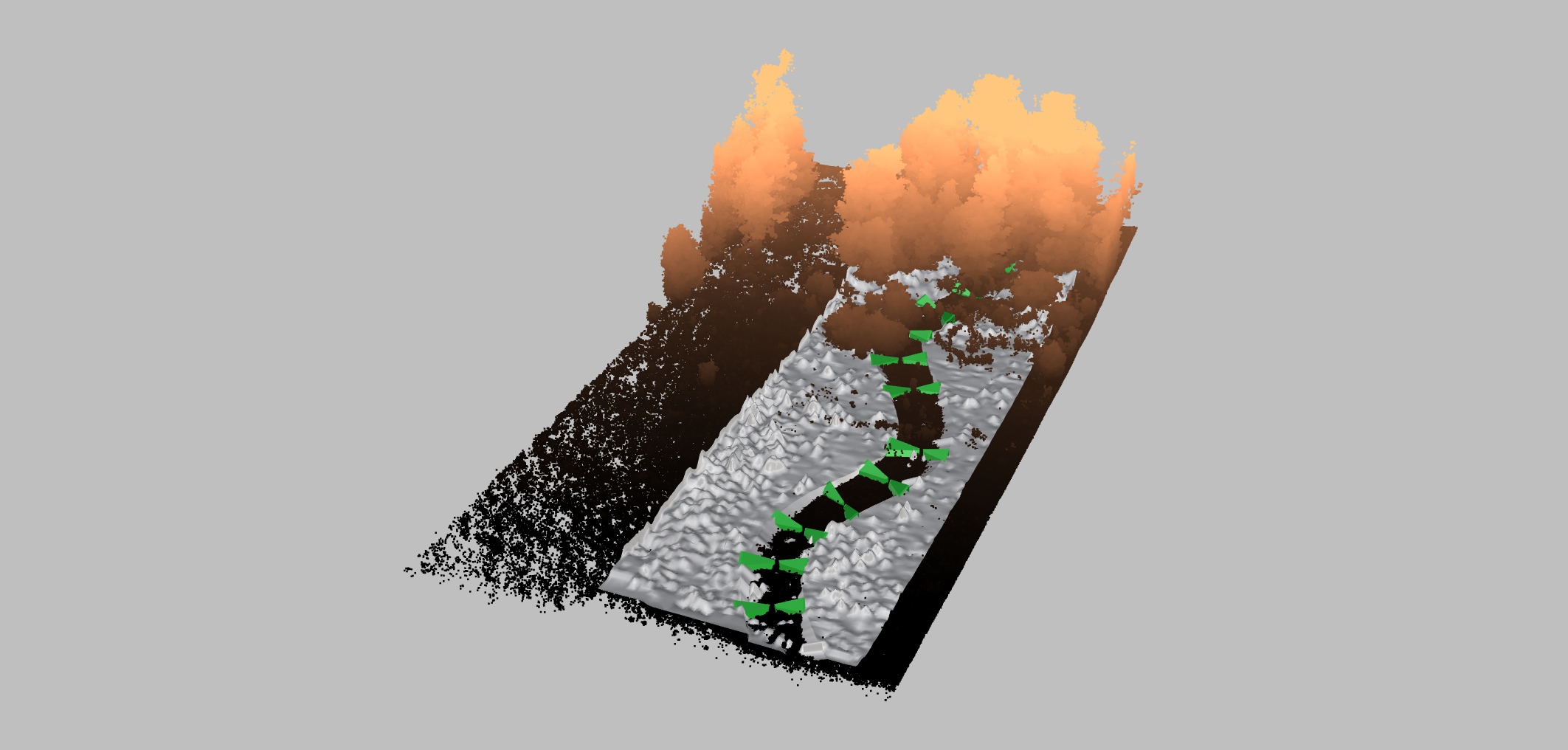

Fish ladder / Dam

Collaboration with TAM

Designed in the Netherlands, 3D printed in Canada! Digital fabrication knows no borders. The first parametric fish ladder design was produced successfully by our partners at Twente Additive Manufacturing.

Fish ladders (vispassages) are structures built along obstructed waterways to facilitate the natural migration patterns of various species of fish. But as each location is unique, so should be the design and the production strategy.

Parametric modeling allows us to iterate design choices to fit specific environments (such as the 3D scanned data from Canada), resulting in highly customized solutions. At the same time, 3D concrete printing allows for the production of unique elements at no added cost.

Our partners at Twente Additive Manufacturing (TAM) not only printed flawlessly but also placed the first few prints on location to test the water flow and installation method. The design here uses a concrete shell and a vernacular material or the filling.

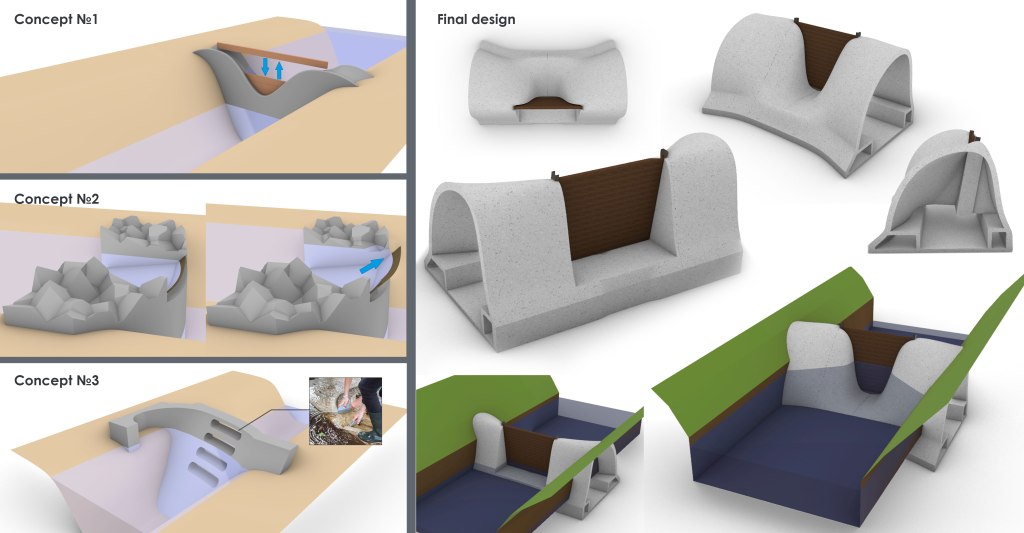

Collaboration with TWW

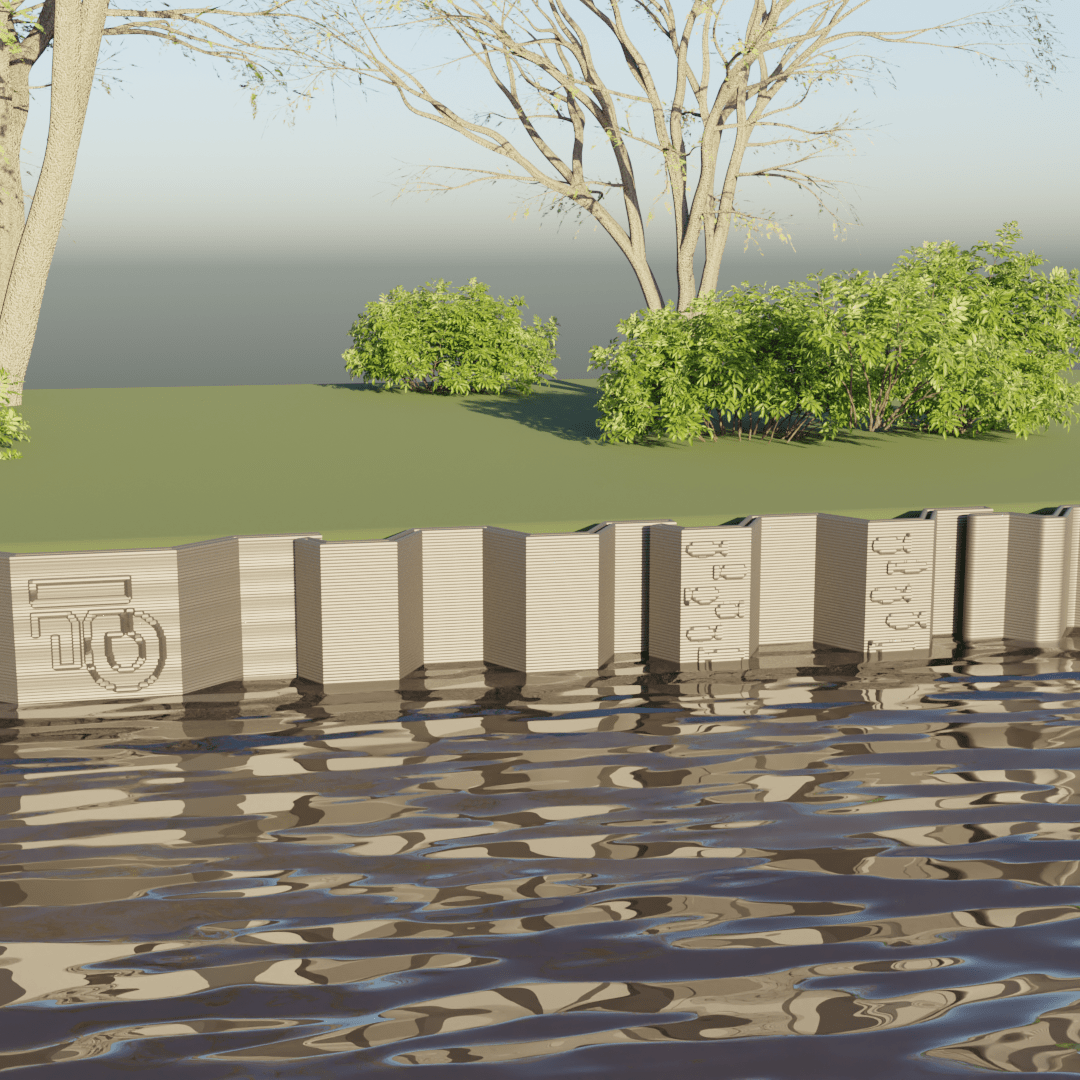

A parallel development under the topic of water infrastructure was done in collaboration with TWW (Twentse Weg- en Waterbouw). The dam was intended for a riverside on the terrain of Lankheet with a requirement to manage a water elevation of 80 cm. A brainstorm session with TWW and Lankheet estate representatives was conducted as well as several co-design moments. This lead to three main concepts out of which one final design was developed with main focus on hydrodynamics, printability, aesthetitcs and installation.

The final design was segmented and prepared for 3d print in Saxion’s concrete lab. The different pieces were assembled and glued together by the team.

The dam was printed and assembled at Saxion’s concrete lab. The result was a structure of 2.2m length, 1.3m height, and 1.5m depth with a total weight of 1.5 tonnes.Green pigment was added irregularly to create a pattern. The impressive structure was prepared for transport by adding reinforcement at the bottom two channels. This way, 3D printing and casting of concrete were combined.

A custom-made U-profile was installed as a slot for 4 planks. By adding and removing the planks, the water level gets adjusted.

The dam was picked up and installed on location by TWW.

Selection Method: study cases

After a 3-part session with TWW using the selection method, two specific cases surfaced as potential developments for 3D concrete printing.

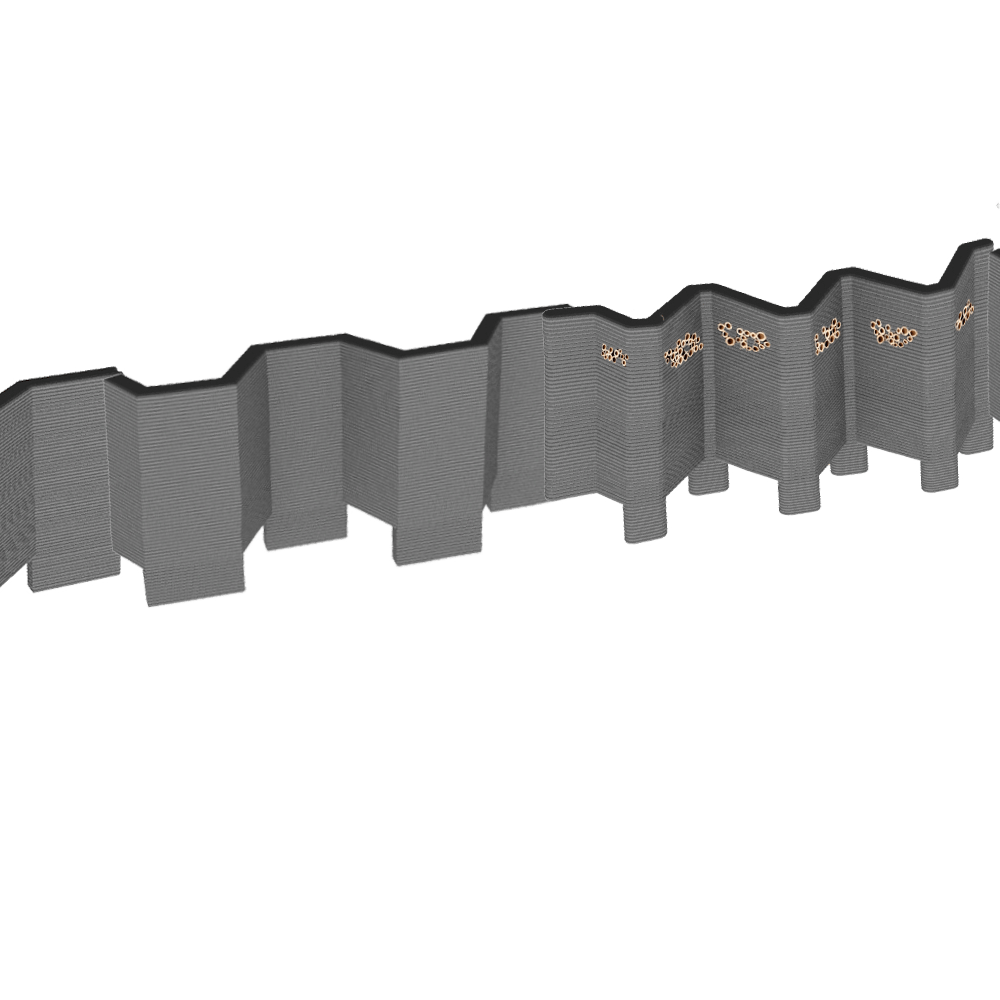

1) Dam profile

The top of dam profiles in streams and rivers rot (relatively) quickly. This is because they get from wet to dry and vice versa quite often. Wood as a material is not suitable for such a situation but it is currently used due to the ease of handling. The piece that is always under water or always remains above water does not have this problem so the focus of this research was on printing an element to be placed at the critical level. Here, various texturing, as well as function integration, were explored in the designs.

2) Manhole

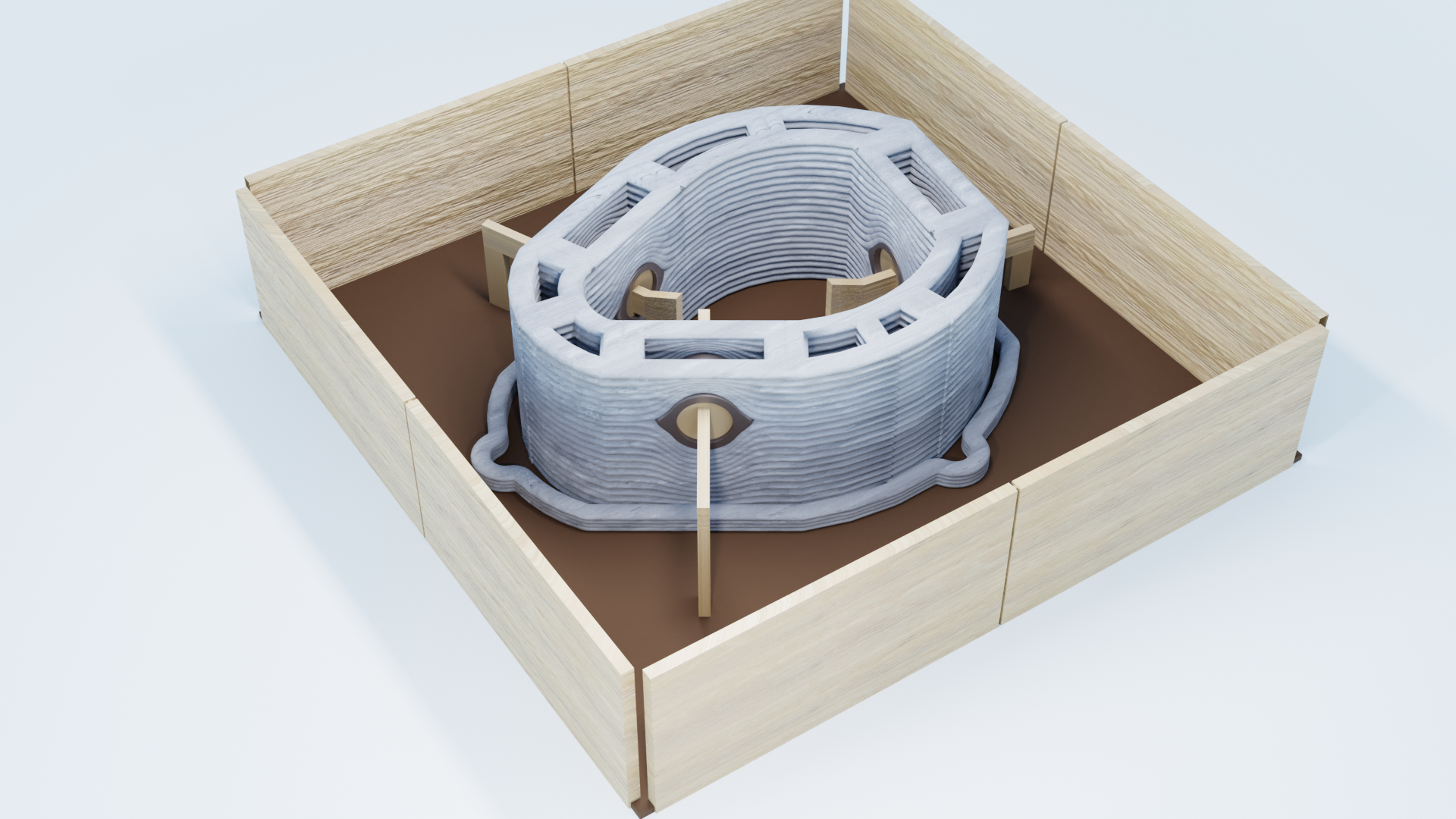

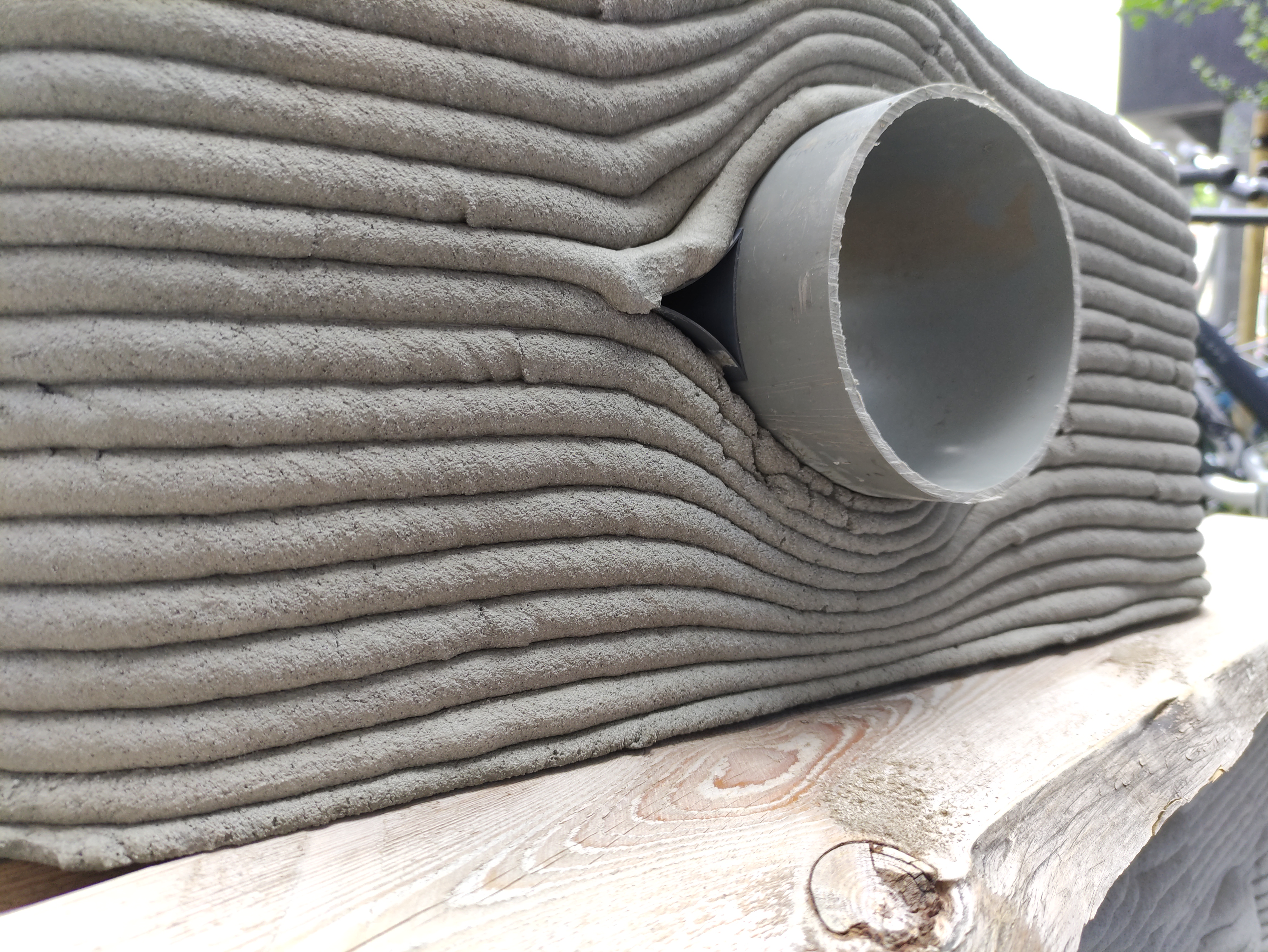

Manholes are essential for underground structures. In the common case, these objects are made by casting concrete in a fixed mold. The interesting thing about this type of product is that it is not always possible to say with 100% certainty in advance whether the product will fit (8 out of 10 times it goes well, according to expert experience). This is mainly due to the fact that you can actually only look in advance at the drawings that are known, if there is an error in these drawings, it immediately goes wrong when placing. The most challenging part is printing the openings for the pipes as they are a perfect circle, quite difficult to achieve. To tackle this challenge, a non-planar slicing strategy was used as well as adding an “eye” element on both sides of the hole.

The concept was further developed as a joint of 3 pipes, at different orientations and positions. The “eye” element was also used here. The pipes were laid during printing over pre-allocated holders.